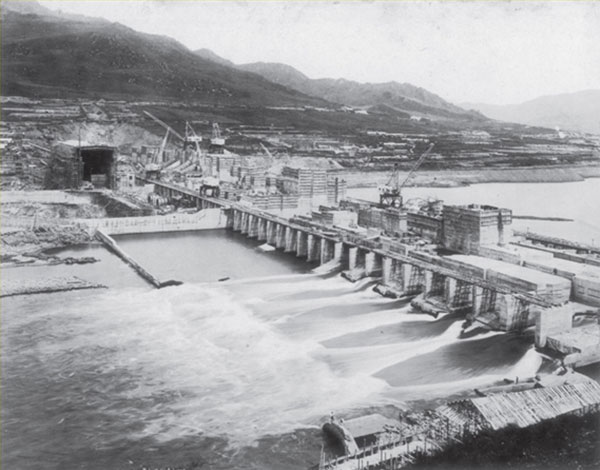

The Second Songhua River in the former Manchuria with a width of 700m-800m. In 1936, a project was launched to build the "Fengman Dam" on it. It was a concrete gravity dam with an embankment length of 1,100 m , a height of 91 m, a crest width of 8 m, a volume of 2.2 million cubic m and a foundation excavation volume of 1.9 million m3, making it the world's largest dam after the Hoover Dam and Boulder Dam (as they were known at the time of construction).

In 1939, cofferdam construction on the left bank began. However, underwater concrete construction in the extreme cold was very difficult. Snake baskets, boulders, and other obstacles froze on the river bottom on the way to the connection of the right bank cutoff, and were not easily removed.

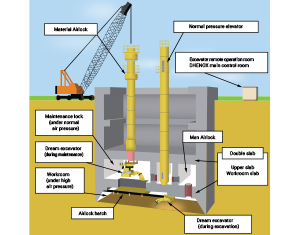

To improve the situation, we decided to use pneumatic caisson technology. The idea was to sink a simple pneumatic caisson to the bottom of the river to remove any obstacles, and then to place concrete to fill the bottom of the caisson and make it part of the watertight wall. The engineers involved in the construction of this dam are the founders of Daiho Corporation. Since our founding, we have consistently refined our technological strength and built the backbone of the construction industry with innovative technologies.