Outline of Institute of Technology

evolution

of

strong technology

new fields and

accepting

the challenge of

developing new

technology

ICT technology

Research Details

Example of technological development mainly conducted by the Institute of Technology and relevant departments

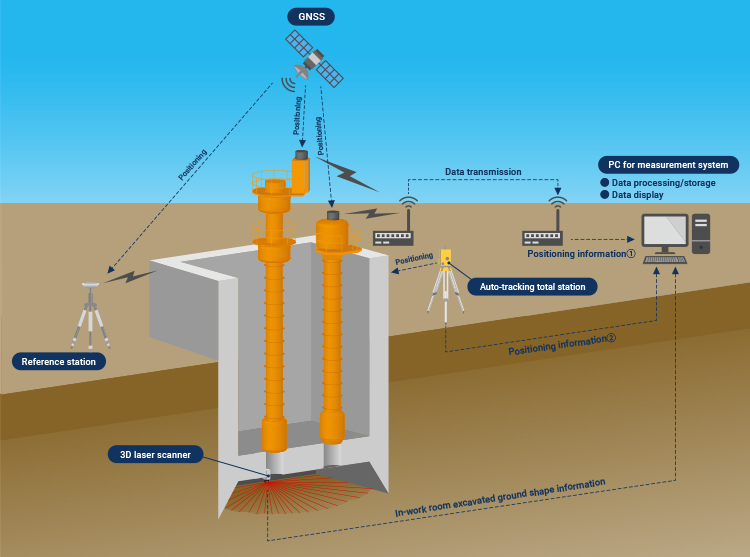

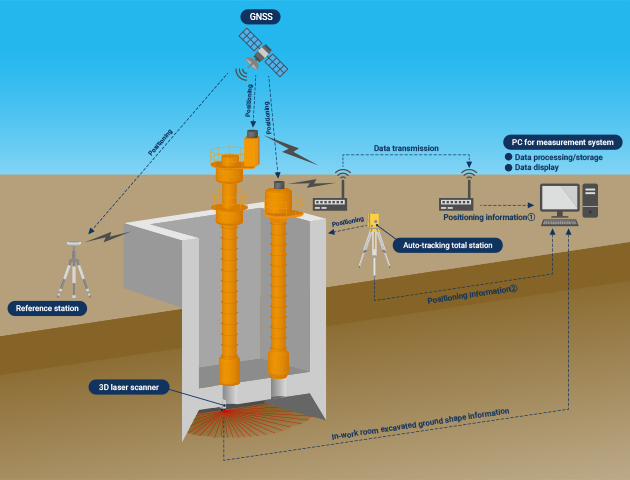

Pneumatic caisson excavation

control system

In order to realize high-precision sinking and excavation control of pneumatic caisson, we are developing a pneumatic caisson sinking and excavation control system, which consists of an automatic measurement system for excavation ground shape and automatic measurement system for caisson position and posture. This system uses such technology as a 3D laser scanner, GNSS, and automatic guiding TS, analyzes the obtained information by using dedicated software, which allows users to grasp the position and posture and which is key to controlling the caisson sinking excavation, as well as the shape of the excavated ground in the box in real time. This system not only realizes high precision sinking and excavation control but also contributes greatly to reducing the workload of workers and improved work efficiency.

Pneumatic caisson excavation simulator

We have developed the "Pneumatic caisson Virtual simulator" for the purpose of providing training, guidance and hands-on experience for operating excavators as part of the Pneumatic caisson Method. The movements of the excavator as well as the terrain are faithfully reproduced down to the smallest detail with the aid of 3D computer graphics, allowing users to experience an operating environment comparable to that of a real excavator, a significant contribution to training and improving the skills of excavator operators. Additionally, games and quizzes for educational purposes have been devised to increase familiarity with the machine so that the simulator can be used as supplementary tool for explaining construction methods at tours and exhibitions.

Pneumatic caisson automatic excavation

By integrating the current technology of pneumatic caisson and new technology, such as the above-mentioned pneumatic caisson sinking and excavation control system and the caisson excavation simulator, and ICT technology, which are combined with the concept of AI, we are developing technology to automate sinking and excavation (material removal). The realization of automatic excavation will develop DX in pneumatic caisson to a great extent.

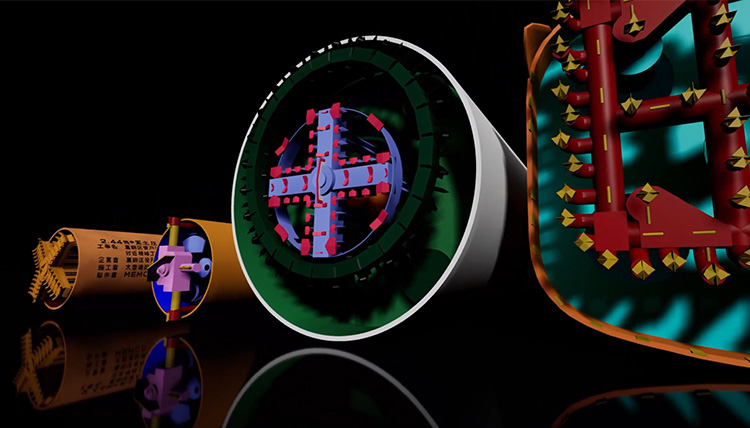

Shield VR (Virtual Reality)

Experience System

We have developed the Shield VR (Virtual Reality) Experience System, which allows users to experience the shield tunneling process at full scale by wearing a head-mounted display.

This system allows users to experience a full-scale shield machine that they would not normally be able to see, and to experience a virtual shield drilling.

The "kukan wo umu - Creating Space" video, which introduces the process of shield construction method, is used not only as an educational tool for staff, but also as a hands-on experience for the visitors at exhibitions and event displays.

Equipment in the Institute of Technology

The Institute of Technology, wherein Daiho Corporation was responsible for the whole process from design to construction, is made of reinforced concrete on the first floor and wood on the second floor, making a hybrid structure. For the wood sections, CLT, timber from forest thinning developed in the MEC Industry as their new business, was used in the walls and columns, and durability and other factors are observed as follow-up. Moreover, by incorporating ingenuity into air-conditioning and electric power, it achieved energy conservation of 54% compared to the normal structure and has received a five-star evaluation by the Building-Housing Energy-Efficiency Labeling System (BELS). On the first floor is the office and laboratory. On the second floor is a training room with a capacity of nearly 70 people, dining room, and napping room.