caisson

technology

technology

harbor technology

/green technology

- Mud pressurization (DK) shield method

- Double-O-Tube (DOT) shield method

- Developing Parallel Link Excavation (DPLEX) shield method

- Jack-driven Developing Parallel Link Excavation (J-DPLEX) shield method

- Detaching And Proceeding to dig Piping (DAPPI) construction method

- Mud pressurizing propulsion method

Civil Engineering Business: Double-O-Tube (DOT) Shield Method

The shield method for building multiple circular tunnels

Outline of the construction method

The DOT (Double-O-Tube) shield method is a construction method for building multiple circular tunnels by excavation using the DOT shield with multiple cutters engaged like gears and assigned on the same flat surface. The basic configuration is a dual type combining two cutters in the vertical and horizontal directions, and dual tunnels are built using a mud pressure shield combining two spoke-shaped or fan-shaped cutters. There have been more than 17 projects in Japan and overseas altogether.

Characteristics of the construction

method

It can reduce unnecessary the cross-sectional surfaces of tunnels on railways and roads. Since the occupied area can be reduced, lots of waste can be omitted.

By freely combining circles in the vertical and horizontal directions, the optimum cross-sectional shape can be chosen in accordance with the surrounding conditions and work conditions, which contributes to dealing with the proximity and intersection of existing structures.

Since cutters are assigned on the same flat surface, it ensures the improved balance of cutting resistance of cutters associated with excavation, which makes it applicable to controlling the shield position, stabilizing cut faces, and work with a wide range of soil properties.

With few unnecessary cross-sectional surfaces, the excavated cross-sectional areas can be reduced, which leads to a reduction of construction byproducts. Furthermore, in the case of the horizontal dual type, construction depth and shaft depth can be reduced, and as for the vertical dual type, the occupying width and shaft width can be reduced, making it possible to reduce costs and improve economic efficiency.

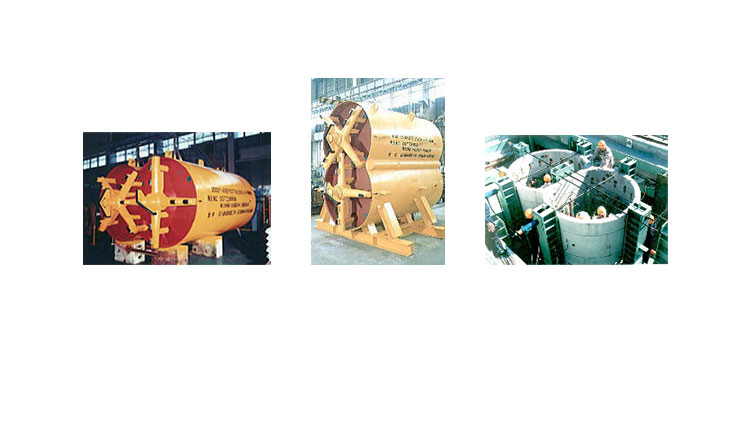

Development of DOT shield method

Under the concept of using the underground space, the method has been developed as an advanced form of the Mud Pressurization Shield Method. By conducting horizontal and vertical dual type demonstration experimental construction, we confirmed safety and workability. At the same time as the development of this construction method, we also developed a segment and conducted bending tests of a single unit, ring loading experiment, and other tests.

demonstration

experimental

construction

(φ2.50m× H4.185m)

experiment

Our Works

-

- Work name

- Route 54 New Traffic System

Rijou Shield Work

- Client

- Hiroshima national Road Construction Office

Ministry of construction

- Construction period

- H1.10 to H6.5

- Work location

- Hiroshima Prefecture

- Application

- New traffic

- Outer diameter of the machine (m)

- φ6.09×W10.69

- Work extension (m)

- 850

-

- Work name

- Narashino City, Kikudagawa No.2 Trunk Sewer

Construciton Work 3

- Client

- Japan Sewage Works Agency

- Construction period

- November 1990 to February 1994

- Work location

- Chiba Prefecture

- Application

- Sewerage

- Outer diameter of the machine (m)

- φ4.45×W7.65

- Work extension (m)

- 586 117

-

- Work name

- High Speed Railway Line No. 4

Chayagasaka Park Section

- Client

- Transportation Bureau, City of Nagoya

- Construction period

- H11.2 to H14.8

- Work location

- Aichi Prefecture

- Application

- Subway

- Outer diameter of the machine (m)

- φ6.52×W11.12

- Work extension (m)

- 1007

-

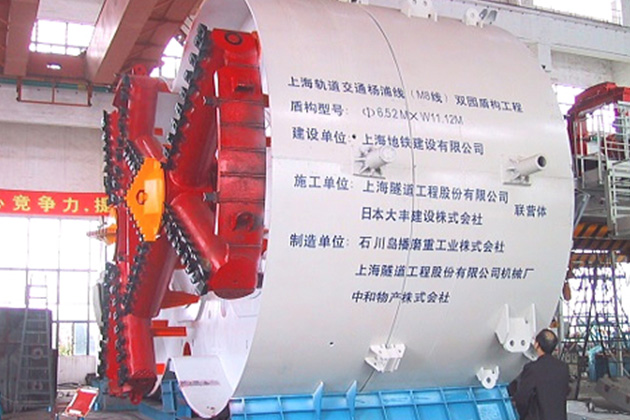

- Work name

- Shanghai Metro Line 8

(M8) Double Circular Shield Tunnel Process

- Client

- Shanghai Shentong Metro Group Co.,Ltd.

- Construction period

- H15.1 to H16.6

- Work location

- China

- Application

- Subway

- Outer diameter of the machine (m)

- φ6.52×W11.12

- Work extension (m)

- 866 893 929