caisson

technology

technology

harbor technology

/green technology

- Mud pressurization (DK) shield method

- Double-O-Tube (DOT) shield method

- Developing Parallel Link Excavation (DPLEX) shield method

- Jack-driven Developing Parallel Link Excavation (J-DPLEX) shield method

- Detaching And Proceeding to dig Piping (DAPPI) construction method

- Mud pressurizing propulsion method

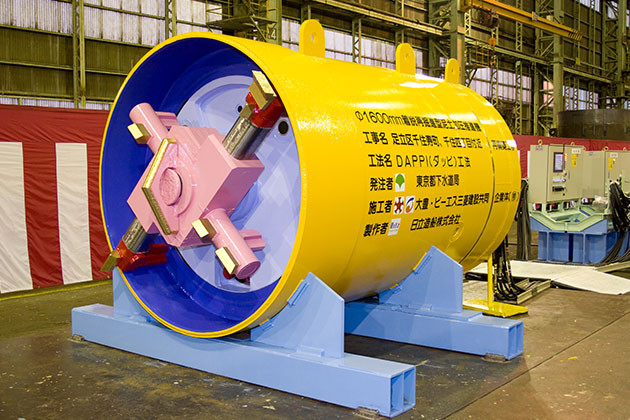

Civil Engineering Business: Detaching And Proceeding to Dig Piping (DAPPI) Construction Method

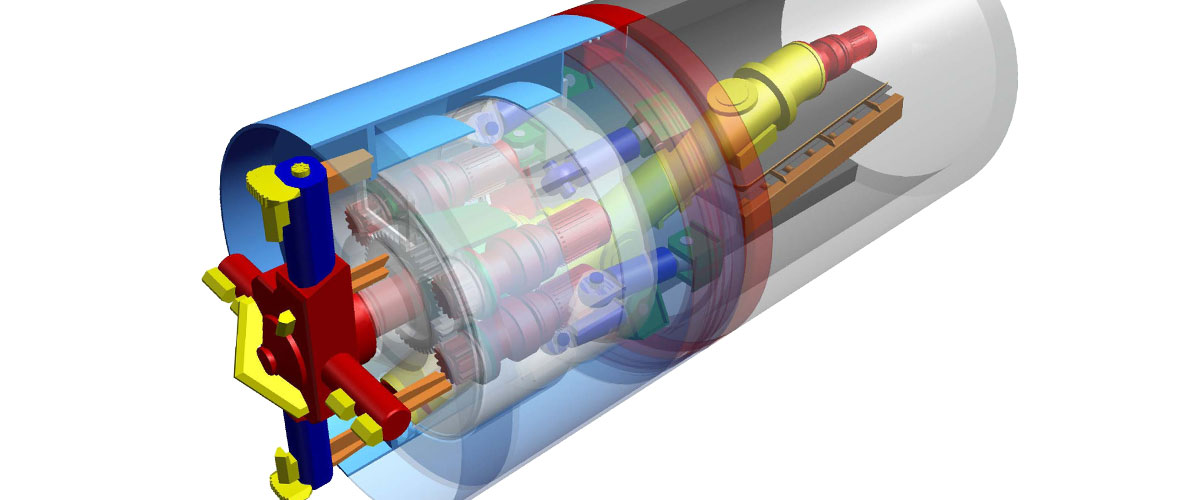

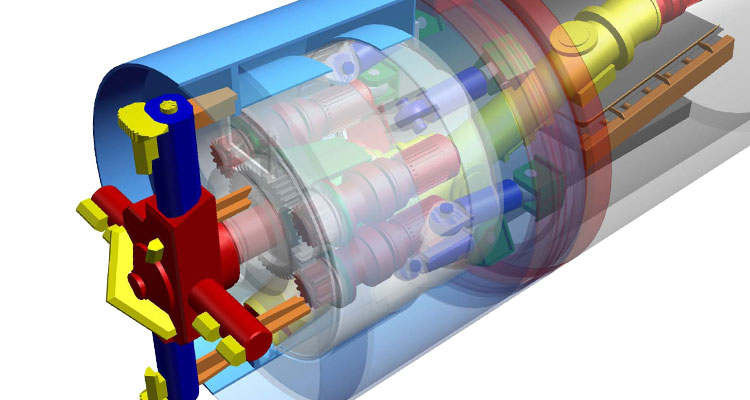

Construction method which allows cutter driving part to be removed from shaft in order to remove obsticles and restart excavating after attacing it again.

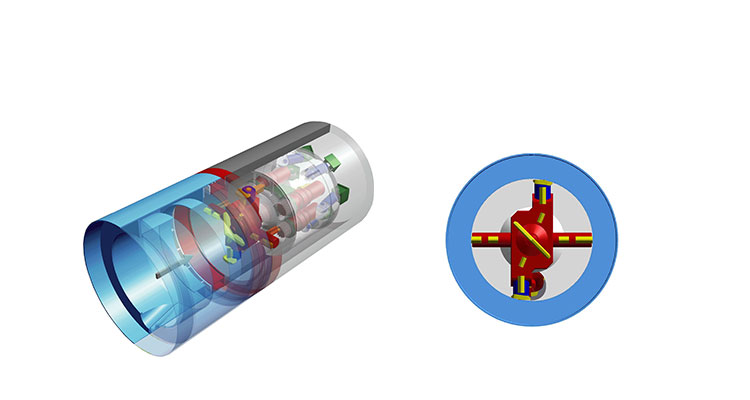

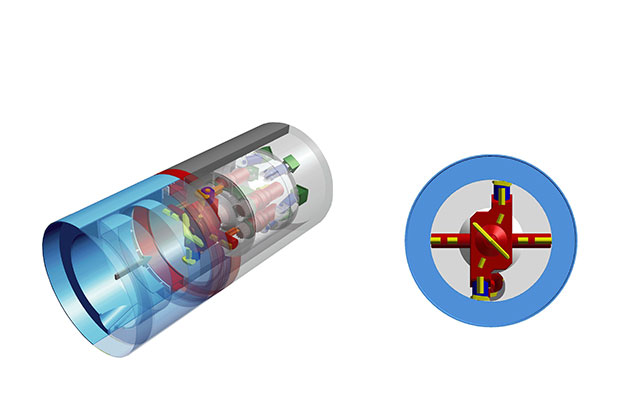

Outline of the construction method

The DAPPI construction method is a construction method for building pipelines by pulling the cut the cutter driving parts out of the outer shell of excavator, removing obstacles from the hole, and excavating again with the cut the cutter driving parts attached. This is used when shafts cannot be installed for removing underground obstacles due to peripheral conditions. This construction method was named after ecdysis because a series of pulling out motions resembles the image of the ecdysis of insects and shrimp from their outer shells. It is also an abbreviation for “Detaching And Proceeding to dig Piping.”

Development of the propulsion method for removing obstacles from the equipment and example of sewerage work

Characteristics of the construction

method

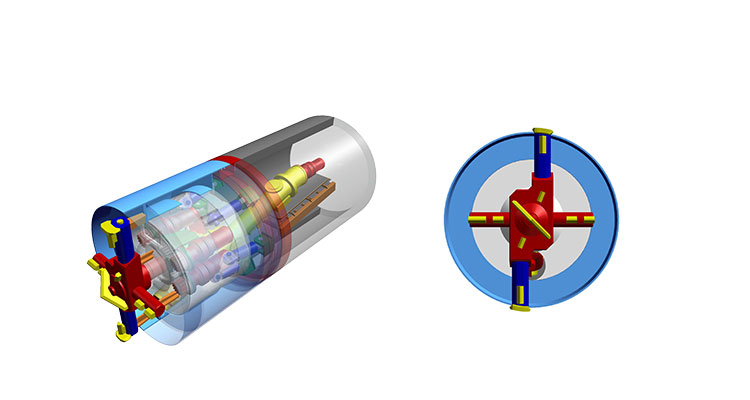

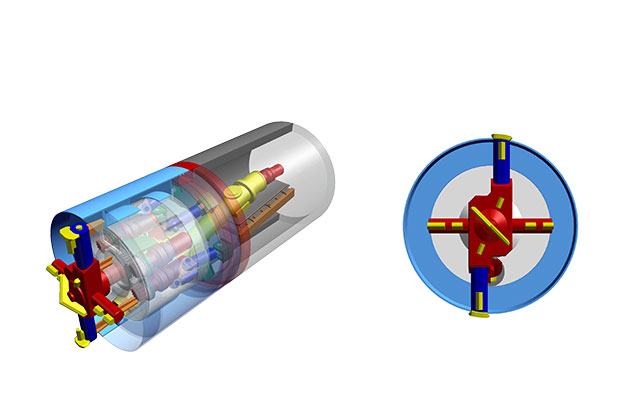

For reaching the existing manholes or existing pipelines, it can be applied as a recovery-type propulsion construction method that allows for recovery and reuse without disassembling the cutter driving parts.

Since the cutter can be extended and contracted from the machine via remote operation, the operator can safely pull and refit the cutter driving parts without stepping in front of the cutter.

Since large workspace is ensured by pulling out the cutter driving parts, obstacles, such as remaining piles, can be safely removed. Compared to when removing them by constructing shafts on the ground, it does not need the occupation of the road and frequent discussions with residents in the vicinity, contributing to reducing the work period and costs.

Application scope of DAPPI

construction method

Also applicable to the propulsion method using the propulsion pipe of 1,350 to 3,000 mm in nominal diameters and super-large diameter propulsion and shield method. By downsizing cutter diameter and considering cutter torque, it can also be used for work with different pipe diameters.

DAPPI Method Technology Study

Group

This study group has been established in 2007 to improve and disseminate the technology of the method and consists of 11 companies as regular members and 4 companies as supporting members.

DAPPI Method Technology Study Group Web Site

Our Works

-

Senjutatsuta-cho, Adachi-ku

Senjutatsuta-cho, Adachi-ku -

Reconstruction Part 4 for Senjunakai-cho, Adachi-ku

Reconstruction Part 4 for Senjunakai-cho, Adachi-ku