caisson

technology

technology

harbor technology

/green technology

- Mud pressurization (DK) shield method

- Double-O-Tube (DOT) shield method

- Developing Parallel Link Excavation (DPLEX) shield method

- Jack-driven Developing Parallel Link Excavation (J-DPLEX) shield method

- Detaching And Proceeding to dig Piping (DAPPI) construction method

- Mud pressurizing propulsion method

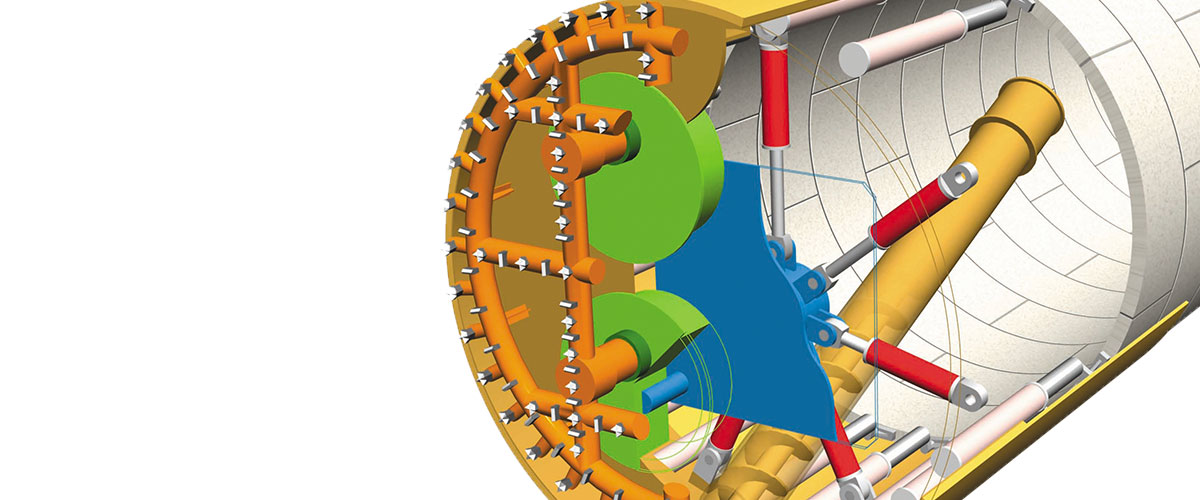

Civil Engineering Business: Jack-Driven Developing Parallel Link Excavation

(J-DPLEX) shield method

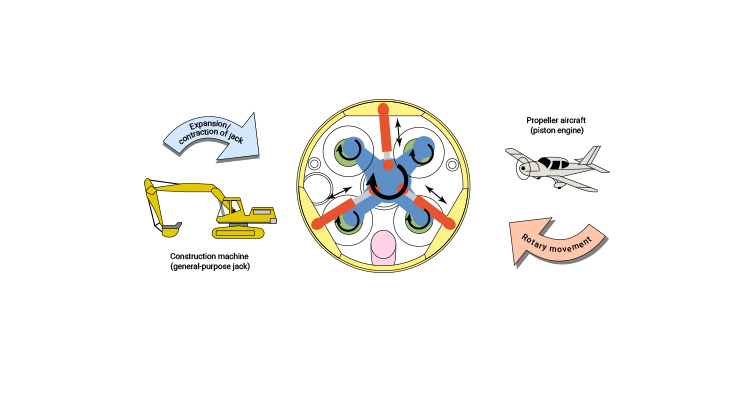

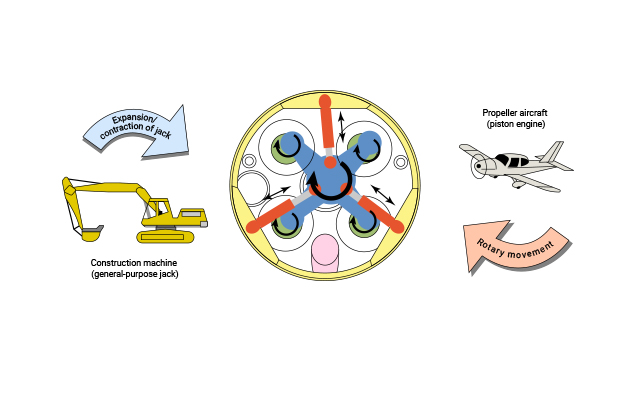

Shield tunneling method in which cutters are driven by hydraulic jacks to rotate and build tunnels.

Outline of the construction method

This method replaces the method using the rotational driving force of the cutter with the conventional configuration of the drive motor and gear to make use of the expansion and contraction of the jack with the aim of reducing the costs of developing a parallel link excavation shield even further.(Patent No. 2939201 filed on Apr.9,1997)

contraction of the jack (drive section inside the shield)

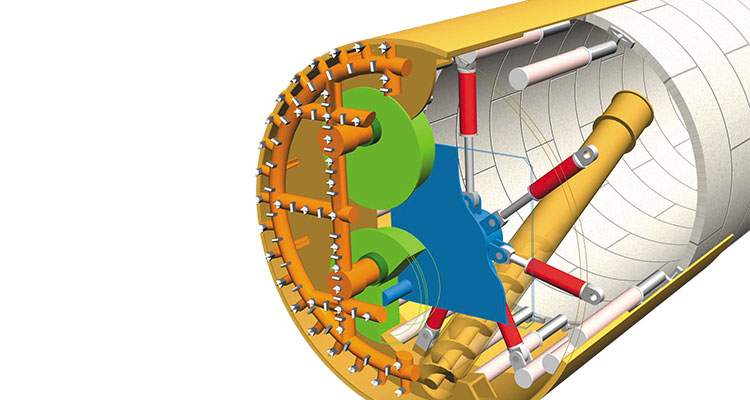

Characteristics of the construction

method

By replacing the configuration using the drive motor, pinion, and gear with a drive mechanism using a hydraulic jack, the drive section becomes simple, which allows for reduction of the manufacturing costs of the shield and easy maintenance, thereby achieving cost reductions. Furthermore, as the hydraulic jack of the same specification/structure as those adopted for general construction machines is used, adequate durability is ensured. Thus, this method is also applicable to long-distance excavation.

Since the drive section has no motors and the drive jack can be assigned in a plane, the length of the shield machine can be shortened. This enables shaft costs to be reduced, contributing to reducing the overall cost for the work.

Compared to the conventional mud pressurization shield, the electric energy used for driving the cutter can be reduced by 10% to 30%. In particular, the substation can be small in size, leading to cost reductions.

An extremely simple control method through detection of the expansion and contraction position has been adopted for the drive jack; therefore, no complex control is required.

Our Works

-

J-DPLEX shield method

J-DPLEX shield method -

Cutter drive section State of adoption

Cutter drive section State of adoption